Plasma-sharpened diamond tools

Sharp. Sharper. Plasma-sharpened.

Summary

The plasma sharpening process developed by us makes diamond-coated tools sharp again.

The process is scalable and the sharpness of the polish can be perfectly adapted to the respective requirements of the tool. In this way, in close cooperation with a major German tool manufacturer, specifically sharpened diamond tools are created that are second to none.

Advantages

- Optimized processing quality

- Improved surface quality

- Reduction in machining forces

- Long service life extension

- Cost savings

Use

Plasma sharpening is particularly suitable for diamond-coated tools of all kinds.

Inserts / cutting inserts

Their indexable inserts and cutting inserts are coated with diamond and plasma-sharpened. The rounding radii of the tools are specifically adjusted to the requirements for processing a wide range of materials. This means that even relatively thick layers can be used without sacrificing the sharpness of the tool.

The advantage is sharper cutting edges when machining:

- CFRP and GFRP (carbon fiber and glass fiber composites)

- Low to medium alloyed aluminum-silicon materials

- Wood

Thanks to the flexibility of the plasma sharpening process, almost all plate geometries can be sharpened.

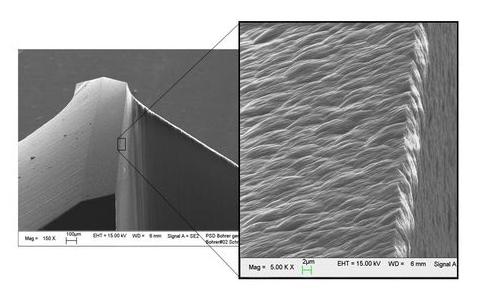

Sharpening is usually achieved by partially removing the diamond layer from the flank face. In most cases, the rake face is not machined, thus ensuring very high wear resistance. This makes it possible to set the rounding radius of the cutting edge independently of the coating thickness, especially for very thick and wear-resistant coatings.

Drill

The main and secondary cutting edges of your drill bits are diamond-coated and plasma-sharpened. The improved sharpness reduces the cutting forces and the load on the workpiece.

This is particularly advantageous for processing CFRP materials (carbon fiber composite material). Thanks to the optimized sharpness, a significant improvement in edge quality can be achieved on the hole exit side.

End mill

The main cutting edge of your straight-fluted end mill is diamond-coated and plasma-sharpened. As a rule, sharpening is achieved by selective and partial removal of the diamond layer from the flank face. The rounding radius can therefore be adapted to the requirements of the machining task regardless of the diamond layer thickness.

PCD cutting

The plasma process developed by GFD is used to sharpen PCD (polycrystalline diamond) cutting edges in a targeted manner. This reduces the cutting edge rounding radius, which leads to a considerable increase in sharpness. At the same time, the process reduces the sharpness of the cutting edge.

Processing is force-free and takes place at temperatures of less than 200°C. This ensures that the properties of the PCD are not altered by the machining process.

The process can also be applied to PCD cutting inserts with complex cutting profiles.

The advantages of an optimized cutting edge lie in finishing and in the processing of soft materials.