Summary

Technology made in Germany

GFD develops and produces diamond-based products and has established itself as the world’s leading supplier of diamond microtechnology. Our products impress with their outstanding properties in the fields of medical technology, pharmaceuticals, material processing and semiconductor technology.

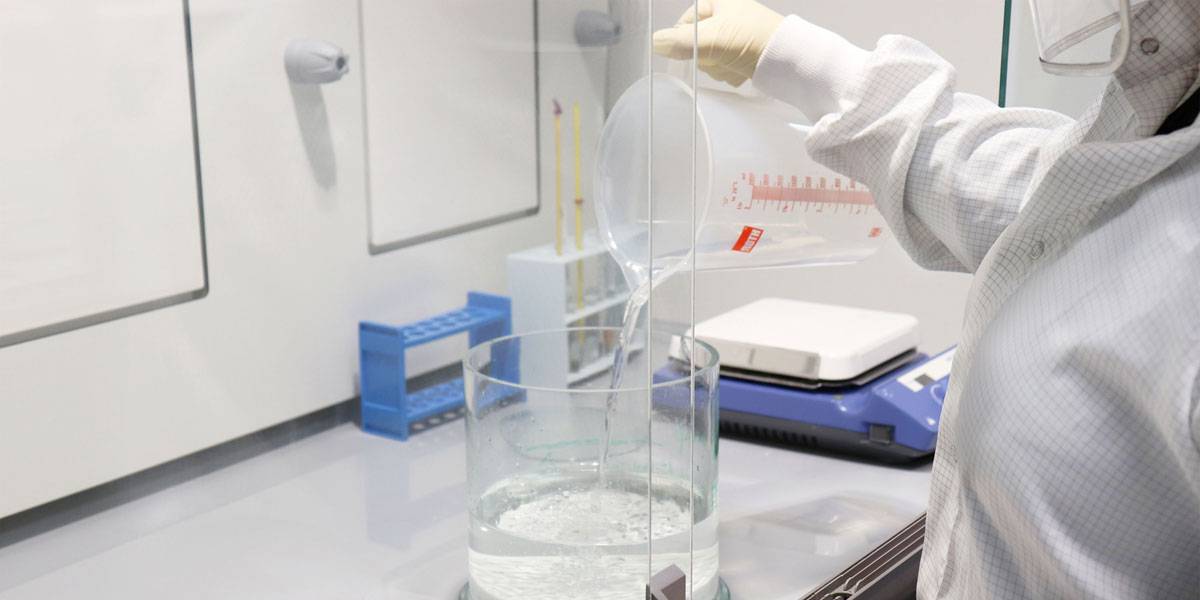

All our products are manufactured in Germany. Using the chemical vapor deposition (

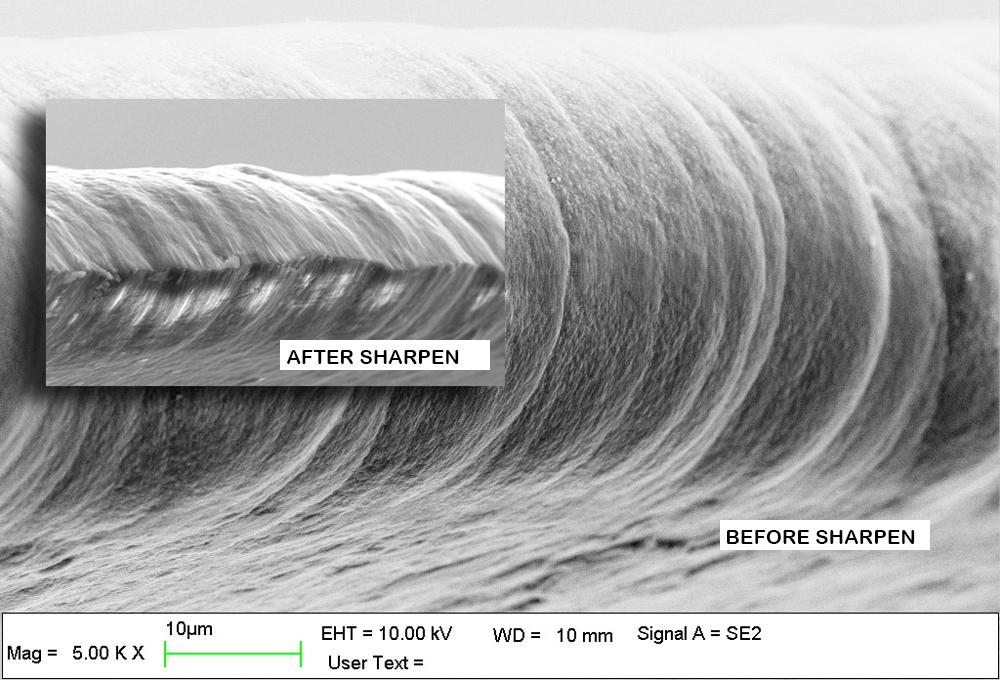

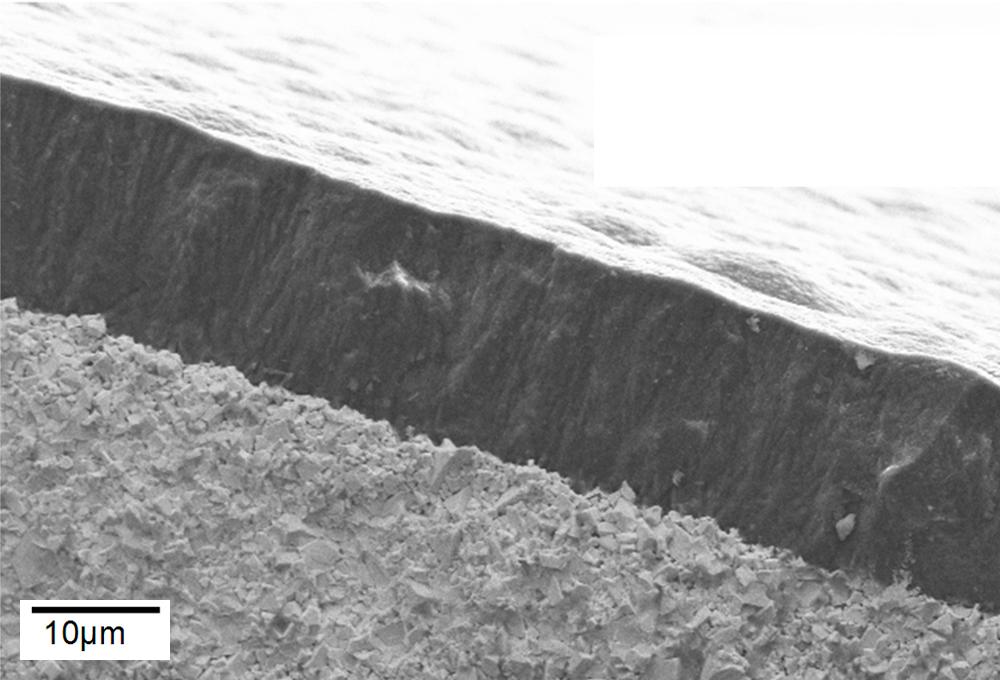

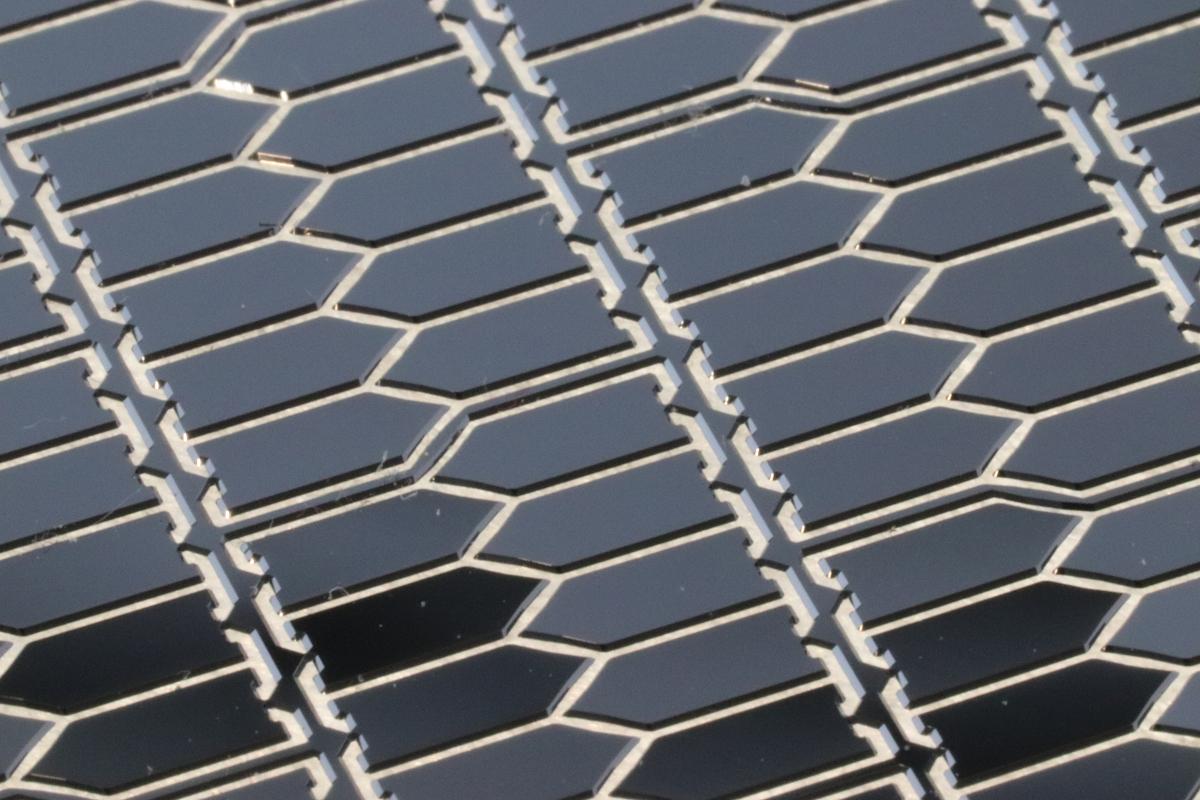

Diamaze PSD (Plasma Sharpened Diamond) cutting edges consist of a carbide cutting edge coated with diamond. The thickness of the diamond layer can vary between

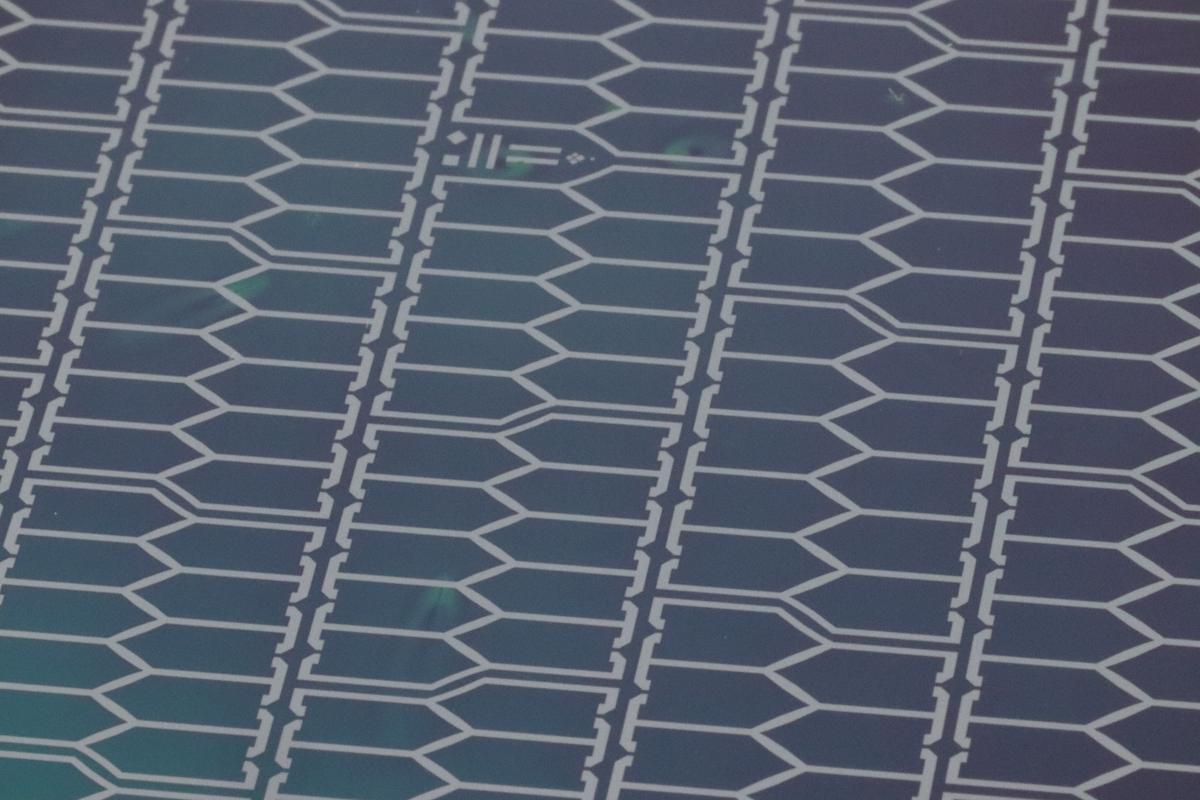

The plasma sharpening process developed at GFD now allows the sharpness of the cutting edge to be significantly increased retrospectively. This makes it possible to achieve a significant increase in service life in combination with optimized sharpness.

Innovation ➜ plasma-sharpened diamond (PSD)

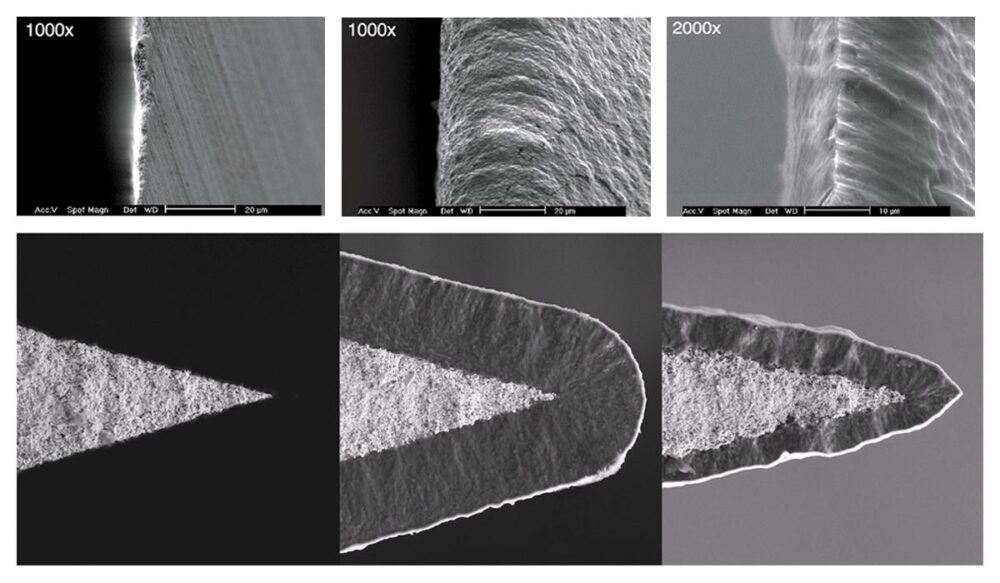

Principle of the production of Diamaze PSD cutting

- Carbide blade without diamond coating

- Carbide blade with diamond coating

- Carbide blade Blade with diamond coating and plasma-sharpened cutting edge

- Left: Cross-section of a diamond-coated carbide cutting edge.

- Right: Cross-section of the same blade after plasma polishing.