Plasma-sharpened diamond blades

Standstill? Wear and tear? Not a chance!

One carbide blade, diamond-coated, plasma-sharpened.

Summary

Diamond cutting blades, extremely wear-resistant and super sharp. These blades meet the highest requirements.

We manufacture diamond-coated carbide blades for extremely wear-intensive applications under the name Diamaze PSD (Plasma Sharpend Diamond).

Due to the exceptional hardness of diamond, Diamaze PSD blades actually achieve service lives that are up to 1000 times longer than conventional steel blades and up to 40 times longer than carbide and ceramic blades.

Thanks to the plasma polish used, Diamaze PSD blades have an exceptionally high sharpness. The low maintenance requirements and the associated low set-up costs not only save you time, but also money.

The shape of the cutting blades can be specified by the customer or developed together with GFD. GFD has many years of experience in developing cutting solutions for the benefit of the customer.

Advantages

- Extremely high sharpness of our diamond-coated and plasma-sharpened cutting blades.

- Significant increase in service life combined with constant sharpness over the service life.

- Lower long-term costs for blades, due to the long service life and lower maintenance requirements.

- Reduced machine downtimes and set-up costs.

- Increased efficiency and cost savings due to high yield.

Use

Technology: Use for pulling cuts or rotary cutters (circular knives).

Materials

- BSF (Battery Separator Foil)

- Aluminum foil

- Copper foil

- Metal foils

- Plastic films

- Paper, cardboard

- Composite materials

- Wood

- Fabrics

- Leather

- Carbon fibers

- Kevlar

Areas

- Battery industry

- Films and fiber industry

- Pharmacy and medical technology

- GFRP and CFRP in the aerospace industry

- Textile and paper industry

- Packaging industry

Comparison with uncoated carbide or ceramic blades

Comparison of tool life between carbide, ceramic and Diamaze PSD blades when cutting plastic film (with color pigments).

Improvement in cutting quality

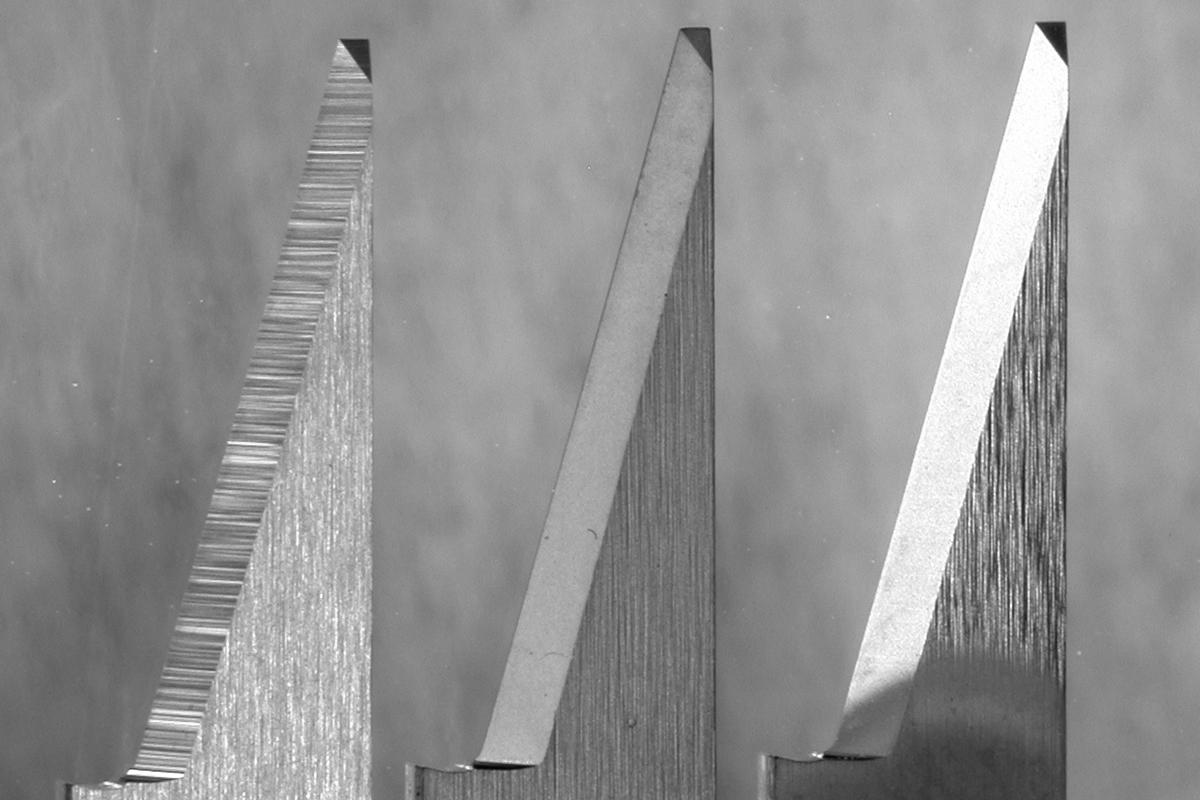

To achieve smoother cutting surfaces, two key factors are decisive:

- Sharpness of the cutting edge (so-called rounding radius)

- The surface roughness on the cutting edge.

Thanks to the plasma sharpening process used by GFD, the sharpness of the blade can be optimally adapted to the material to be cut. The sharpness of the coated cutting edge can even exceed the sharpness of the original cutting edge.

The smooth surface is achieved by using a very fine crystalline diamond coating. Typical surface roughness is in the range of 5 nm to 20 nm (glossy appearance). Further advantages of using diamond are the low adhesion of many materials and the very low coefficient of friction of diamond.

Cutting blades with the following properties can currently be produced:

- Sharpenable cutting angle

15°- 60° - Length and width of the blade

1 mm – 500 mm - Minimum blade thickness

approx. 150 µm - Single-sided and double-sided ground cutting edges can be produced

- Sharpening process is self-adjusting and can therefore also machine extremely complex cutting edge geometries

- Intensity of the sharpening process can be freely adjusted

- The plasma sharpening process allows the rounding radius of the cutting edge to be adjusted as required

Assortment overview

Our diamond-coated, plasma-sharpened cutting blades are available as foil or plotter blades in thicknesses between 0.15 mm and 0.6 mm.

Foil blades

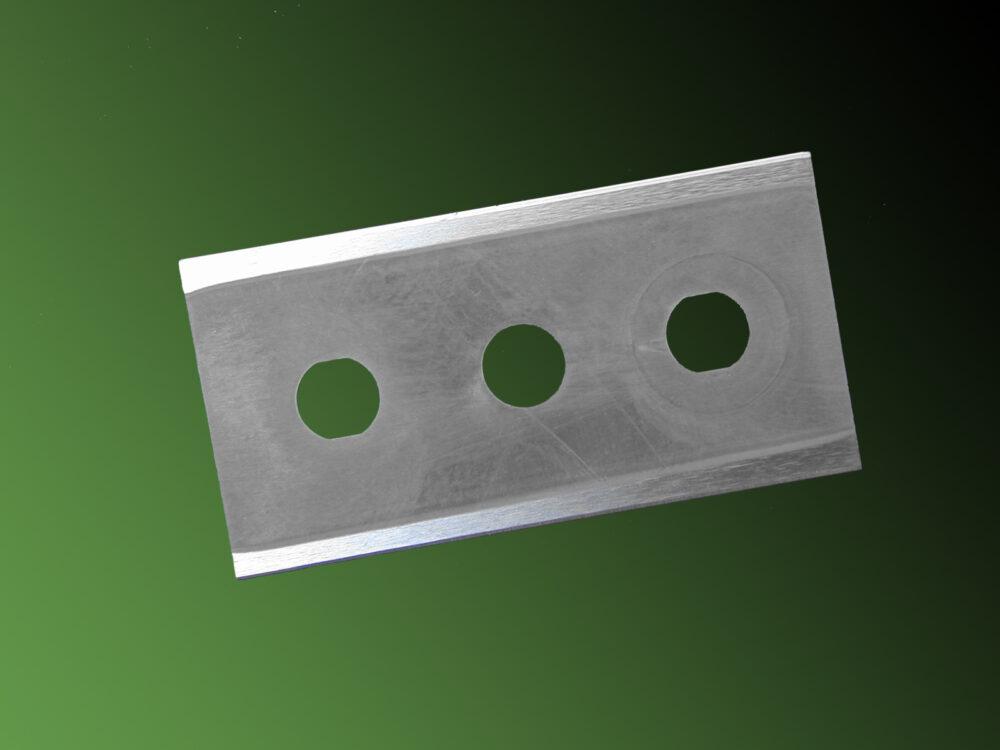

Diamaze PSD foil blades (3 holes)

Item no. / size:

- K.0020.015 / 43mm x 22mm x 0.15mm

- K.0020.020 / 43mm x 22mm x 0.2mm

- K.0020.030 / 43mm x 22mm x 0.3mm

- K.0020.040 / 43mm x 22mm x 0.4mm

- K.0020.060 / 43mm x 22mm x 0.6mm

Diamaze PSD foil blades (slotted hole)

Item no. / size:

- K.0030.038 / 57.5mm x 19mm x 0.38mm

- K.0030.060 / 57.5mm x 19mm x 0.6mm

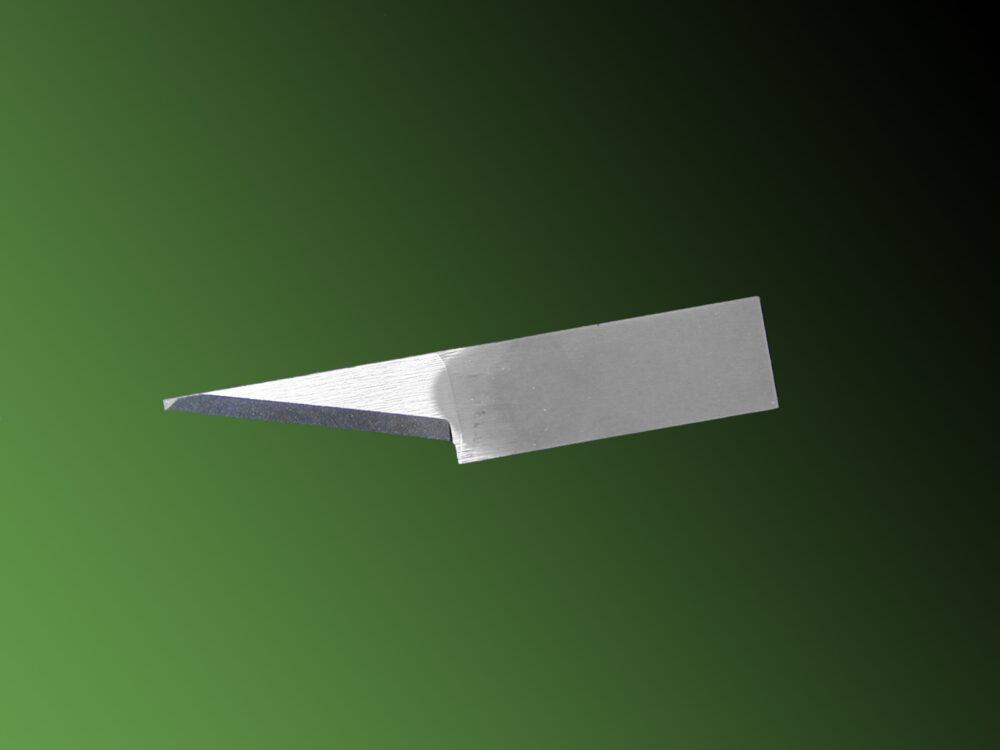

Plotter blades

Diamaze PSD plotter blades

Item no. / size:

- K.0040.055 / 26.5mm x 5mm x 0.55mm 30°

- K.0041.055 / 33.5mm x 6.2mm x 0.55mm R15

You need individual blades

This is also possible. In addition to the existing standard shapes, individual blade geometries can also be produced. We will be happy to advise you when it comes to optimizing your sophisticated cutting solutions. See Research & Services.